Ferrous Metal

Cold Saw Blades [Resharpenable]

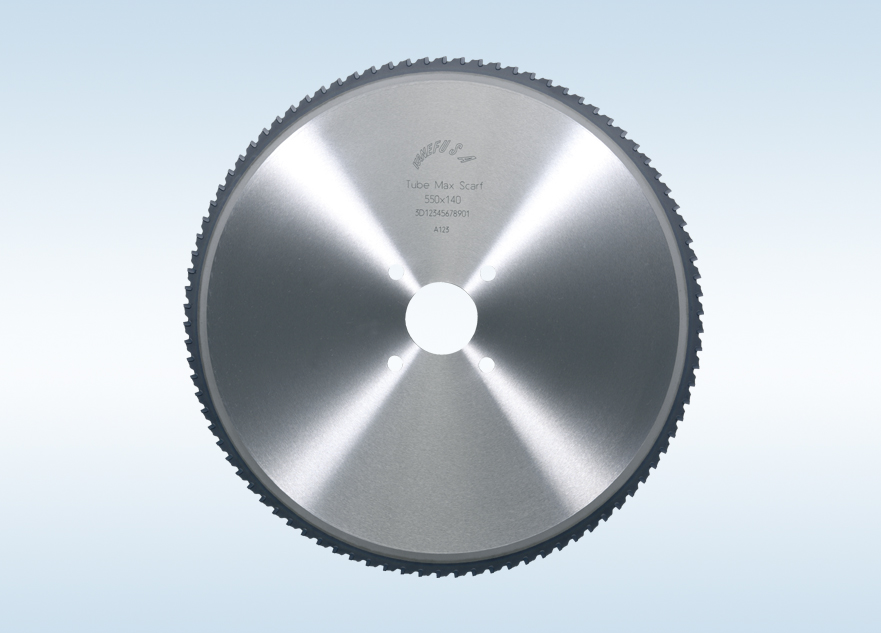

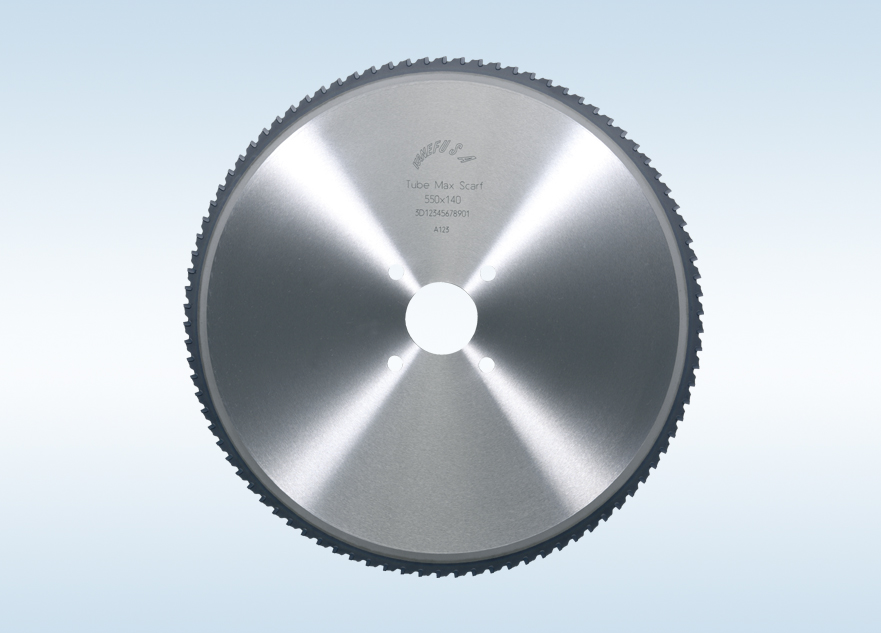

Tube Max Scarf

For pipe cutting with a single and twin flying cut-off machine

• Improved tooth shape and wear-resistant tip grade minimize product defects that occur due to scarfs (unfixed welding beads) on the pipe.

• The proprietary coating realizes a longer service life and improve product stability.

| Application |

For pipe cutting with a single and twin flying cut-off machine |

| Machines |

Single and twin flying cut-off machine |

| EdgeMaterial |

Coated Tungsten Carbide |

Tube Max Orbital

For pipe cutting with an orbital flying cut-off machine

•Improved blade shape and coating achieve better wear-resistance and product lifetime. Maintains stability even when cutting high-tensile steel pipes at high speeds (600m/min), making it possible to increase productivity by speeding up the manufacturing line.

| Application |

For pipe cutting with an orbital flying cut-off machine |

| Machines |

Orbital flying cut-off machine |

| EdgeMaterial |

Coated Tungsten Carbide |

Tube Max

For pipe cutting with a single and twin flying cut-off machine

• Specialized in Heat- and wear-resistance more than Tube Max Scarf, for cutting without scarfs (unfixed weld beads) or less defects occurring due to scarfs.

• The proprietary coating realizes a longer service life and improve product stability.

| Application |

For pipe cutting with a single and twin flying cut-off machine |

| EdgeMaterial |

Coated tungsten carbide |

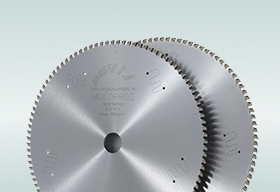

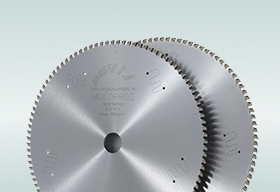

Cold Saw Blade

Universal application and high performance

•Kanefusa cold saw blades can be reground several times

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine (Endo, Mitsubishi, Tsune, Linsinger,Wagner, Heller and others) |

| EdgeMaterial |

Tungsten Carbide and Cermets |

Cold Saw Blades for Single Use

Ferro Max ST-5

Carbon steel solids (C: ≦0.45 %)

With higher wear and adhesion resistant tooth tips, it achieves more stable and longer sawing performance.

| Application |

Cuts solids |

| Machines |

Cold saw machine Vc = 70 m/min - 120 m/min f z = 0.05 mm - 0.07 mm |

| EdgeMaterial |

Cermet |

Ferro Max Ti-5

High carbon steel solids and tubes

Universal application and high performance

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine Vc = 70 m/min - 120 m/min f z = 0.05 mm - 0.07 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferro Max SUS

Improved blade life by newly developed coating

New tip design

| Application |

Cuts solids |

| Machines |

Cold saw machine Vc = 50 m/min - 70 m/min f z = 0.04 mm - 0.06 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferro Max Dies

For Die steel solids

Special coating up to 100% longer tool life compared with Ti-5

| Application |

Cuts solids |

| Machines |

Cold saw machine Vc = 60 m/min - 80 m/min f z = 0.05 mm - 0.07 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferro Max Speed

Higner cutting speed for less cycle time and higher productivity

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine Vc = 200 m/min - 300 m/min f z = 0.05 mm - 0.08 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferro Max Speed LC

Higher cutting speed achieved for low carbon steel.

Special coating and carbide edge up to 100% longer tool life.

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine Vc = 200 m/min - 300 m/min f z = 0.05 mm - 0.08 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

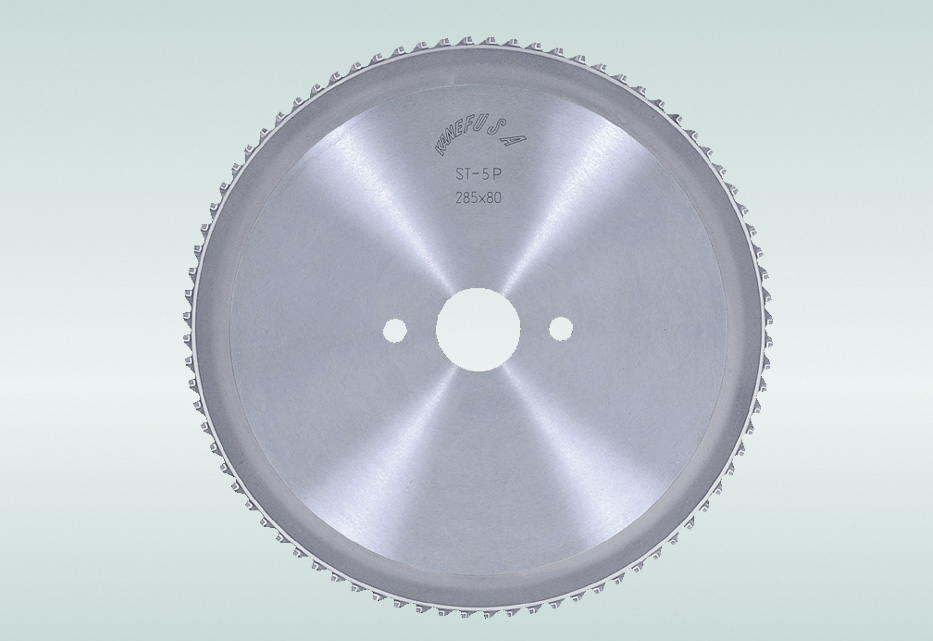

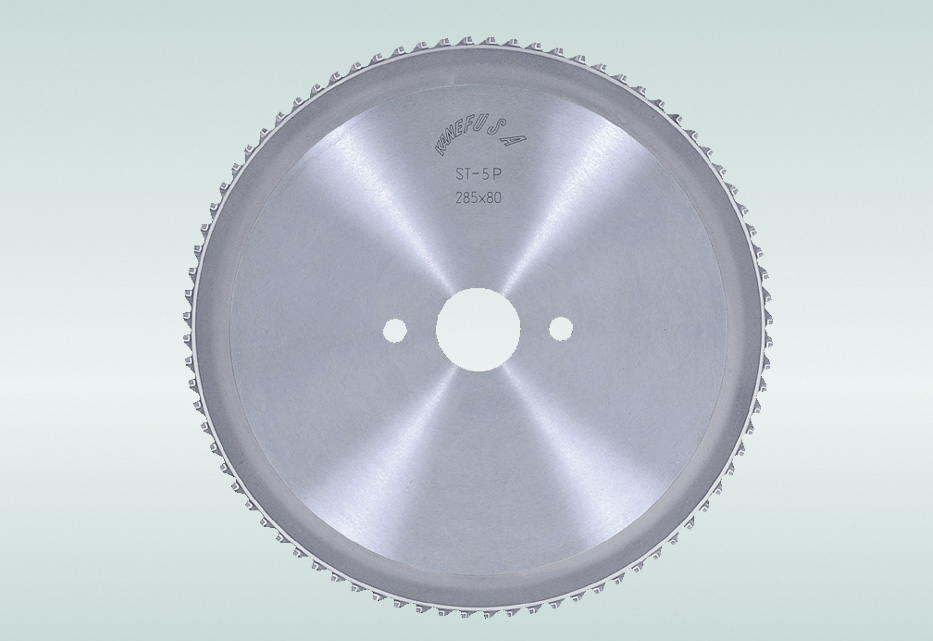

Ferro Max ST-5P

With high chipping resistant cermet tooth edge, it achieves more stable sawing performance in the harsh condition which triggers damages to tooth edges

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine Vc = 100 m/min - 200 m/min f z = 0.03 mm - 0.06 mm |

| EdgeMaterial |

Cermet |

Ferro Max Tube

For thin wall tubes without deformation of the wall

| Application |

Cuts thin walled tubes |

| Machines |

Cold saw machine Vc = 100 m/min - 200 m/min f z = 0.03 mm - 0.05 mm |

| EdgeMaterial |

Cermet |

Ferro Max Super Tube

High cutting speed for thin wall tubes

| Application |

Cuts thin walled tubes |

| Machines |

Cold saw machine Vc = 200 m/min - 300 m/min f z = 0.03 mm - 0.05 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferro Max SUS Tube

Achieve 10 times longer cutting life compared with Ferro Max Tube in difficult stainless steel tube sawing with newly developed special tooth shape, carbide edge and coating

| Application |

Cuts thin walled tubes |

| Machines |

Cold saw machine vc = 50 m/min - 100 m/min f z = 0.03 mm - 0.05 mm |

| EdgeMaterial |

Coated Tungsten Carbide |

Ferrous Saw Blade

Mold Pro II

For cutting stainless steel moldings for automobiles

• Tougher tips means improved chipping resistance.

• A stable cut is acheved.

| Application |

Cutting stainless steel moldings for automobiles |

| Machines |

Beam saws, special saws, cut off saws |

Mold Pro

Various thin walled metal Saw Blade

•Suitable for cutting various compound metals including stainless steel

| Application |

Cuts thin sheets, tubes, profiles |

| Machines |

Beam saws, special saws, cut off saws |

| EdgeMaterial |

Cermet |

Dry Cut Saw Blade

•Dry Cut saw blade is low cutting resistance blade for sawing steel with high resistance against successive shocks.

| Application |

Sawing Reinforcing Rod, Steel Plates, Angle Steel, Pipe, C type Steel, and Difficult-to-machine Stainless Steel |

| Machines |

Circular Saw Power Tool, Sliding Table Sawing Machine |

| EdgeMaterial |

PRO-K |