KANEFUSA for Sustainability

Kanefusa's latest technology with sustainability

The traditional blacksmith method was handed down from our founder into the advanced processing technology. Our Theory and experience built up a foundation of Kanefusa original technology. Now, the technology enables us to propose "Kanefusa sustainable products" for reduction of environmental load. Kanefusa is proud of our contributions to the environment and ecological improvement.

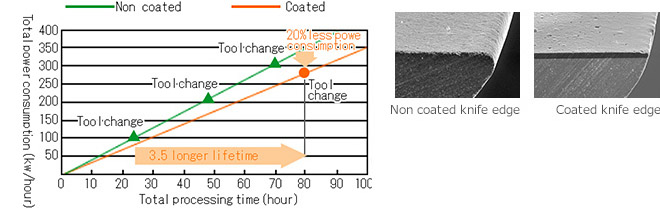

Power saving with original coating technology

Kanefusa's coating technology gains world recognitions for its self re-sharpening effect.

Due to an optimization and combination of backing metals and the coating, it enables longer tool lifetime and 20% less power consumption compared to the conventional knife.

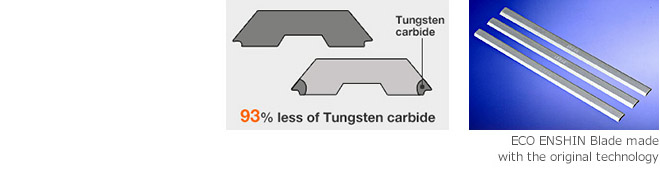

Saving rare metals with the original tipping technology

The Kanefusa's original tipping technology minimized tungsten carbide for the cutting edge. It reduces 93% of tungsten carbide compared to the conventional knife.

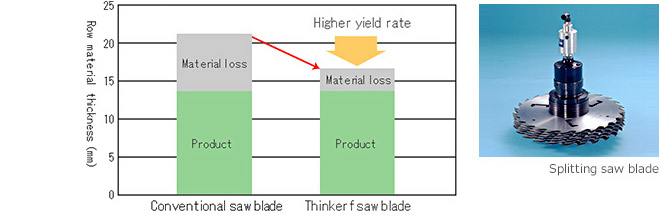

Higher yield with thin kerf technology

Our originally developed Center Lube mist system for splitting application reduces sawing friction and abrasion. Less burning and distortion of saw blade ensures smooth operation. Compared to conventional saw blades, yield rate mproved by 12% and electronic consumption decrease by 22%.

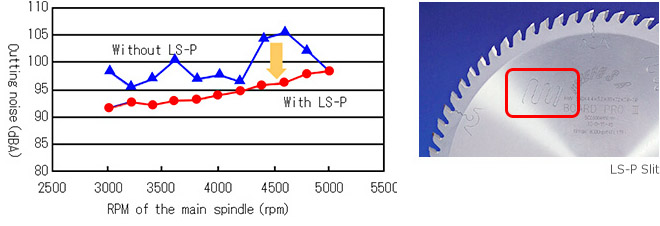

Low noise for better work environment

Polymer is injected into the laser slits (LS-P slits)and this reduces the vibration that causes high tone noise and waving cut.