Cold Saw Blades [Resharpenable]

Cold Saw blade

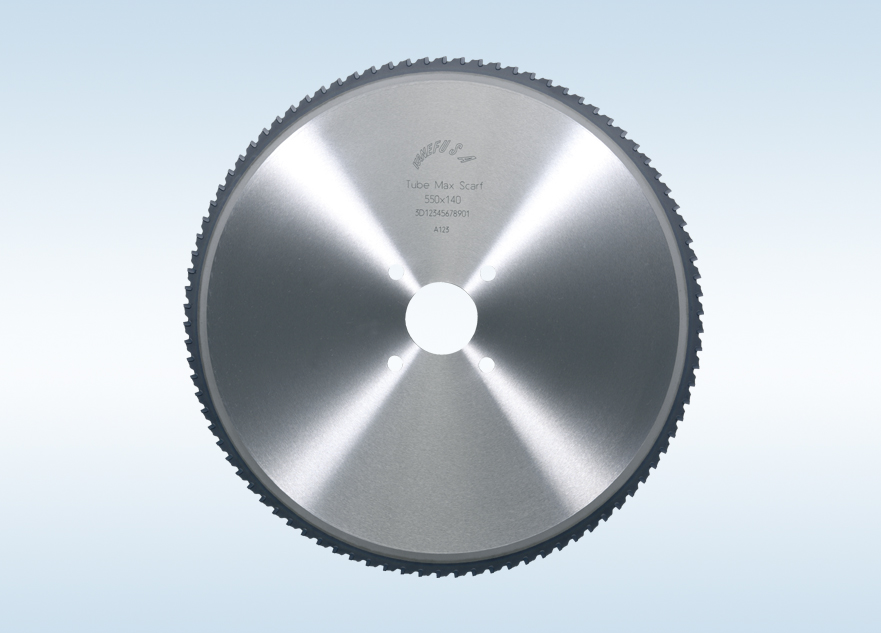

Tube Max Scarf

For pipe cutting with a single and twin flying cut-off machine

• Improved tooth shape and wear-resistant tip grade minimize product defects that occur due to scarfs (unfixed welding beads) on the pipe.

• The proprietary coating realizes a longer service life and improve product stability.

| Application |

For pipe cutting with a single and twin flying cut-off machine |

| Machines |

Single and twin flying cut-off machine |

| EdgeMaterial |

Coated Tungsten Carbide |

Tube Max Orbital

For pipe cutting with an orbital flying cut-off machine

•Improved blade shape and coating achieve better wear-resistance and product lifetime. Maintains stability even when cutting high-tensile steel pipes at high speeds (600m/min), making it possible to increase productivity by speeding up the manufacturing line.

| Application |

For pipe cutting with an orbital flying cut-off machine |

| Machines |

Orbital flying cut-off machine |

| EdgeMaterial |

Coated Tungsten Carbide |

Tube Max

For pipe cutting with a single and twin flying cut-off machine

• Specialized in Heat- and wear-resistance more than Tube Max Scarf, for cutting without scarfs (unfixed weld beads) or less defects occurring due to scarfs.

• The proprietary coating realizes a longer service life and improve product stability.

| Application |

For pipe cutting with a single and twin flying cut-off machine |

| EdgeMaterial |

Coated tungsten carbide |

Cold Saw Blade

Universal application and high performance

•Kanefusa cold saw blades can be reground several times

| Application |

Cuts solids and tubes |

| Machines |

Cold saw machine (Endo, Mitsubishi, Tsune, Linsinger,Wagner, Heller and others) |

| EdgeMaterial |

Tungsten Carbide and Cermets |