STEEL & NONFERROUS

Thin Sawing Technology

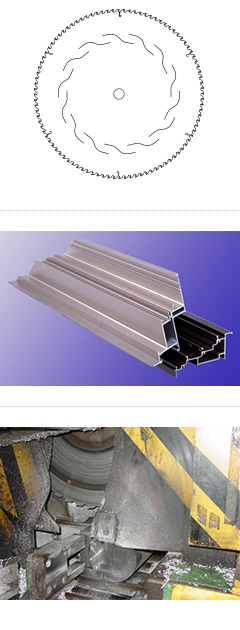

Kanefusa's proprietary flattening and surface grinding methods ensure plates that are distortion free and have a uniform thickness.

In addition to these features, after years of research, we have developed a laser slot pattern that allows reduction of the plate thickness, without compromising its lateral rigidity and ability to run straight.

Polymers are injected into the laser slots and this reduces the vibration that causes high tone noise, structural damage of the carbide grain and a waving cut.

On average the kerf of a Stable sawblade is 20% thinner compared to regular sawblades. This also creates less cutting pressure, which relates to better material recovery rates, cut surface quality, noise and tool life.

Stable sawblade is used on cut-off saws non-ferrous metal solids and profiles.

- The User Value is

-

- Better material recovery rates

- Less swarf that must be recycled

- Better cut quality

- Longer saw life

- Less cutting power is required

- Runs significantly quieter

FM (Ferro Max) - Single Use Cold Saw Technology

Kanefusa is the pioneer of Cold Sawblades for the Single Use. Since 1987, when we released the first version, we have not only improved the quality and durability of the sawblades, but also increased their versatility. Today our product range features different types used for cutting of bearing steel, drive shafts, rails, pipes, shock absorbers and in many more applications.

Superior Technology

Speed

One cold saw machine replaces three band saws or metal saw machines.

- Less space is required

- Fewer personnel are required

- Environment-friendly due to much less lubrication oil

- No sawing sludge to be disposed of

- Less capital outlay

Durability

Kanefusa Tooth Geometry

+ Superior manufacturing technology

+ Cermet or Tungsten Carbide teeth

-------------------------------

= Over 300% longer edge life compared with Metal Saws or Band Saws

Cut Quality

The cut surface and dimensional accuracy, that can be achieved with FM cold sawblades, is superior to that of band saws.

- Eliminates or reduces subsequent manufacturing processes

- Reducing the manufacturing cost of a product

- Allowing higher sales prices of a semifinished product

Process Reliability

Sawblades lose performance after grinding due to incorrect grinding or the plate fatigue and edge wear. Sawblades for single use deliver repeated quality cut after cut, blade after blade.

- Performance is predictable and tool change timing can be scheduled

- Easier handling, because no pick-up and delivery of sawblade is necessary

- The User Value is

-

- Lower cost per cut

- More uptime of the machine and therefore higher productivity and less manufacturing cost

- Better cut quality, higher productivity and process reliability enable Just in Time production

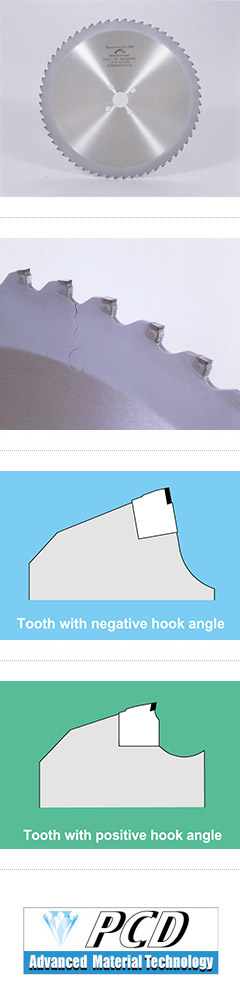

Novametal Pro DIA

Novametal Pro DIA is suitable to cut Aluminum alloys with a silicon content of over 10 %.

Novametal Pro DIA is tipped with polycrystalline diamond (PCD).

Polycrystalline diamond provides extensively longer life than tungsten carbide when cutting Aluminum alloys.

In the past, a certain size of the polycrystalline diamond tooth was required to assure that the tooth was firmly attached to the saw plate.

Because polycrystalline diamond is much more expensive than other cutting edge materials, the sawblade price strongly depended on the tooth size.

We at Kanefusa have developed a technology that allows us to fuse a very small PCD tooth to a tungsten carbide substrate, which is brazed to the saw plate. In this way we can optimize the use of the polycrystalline diamond and make the single use of PCD tipped sawblades possible.

For many reasons, sawblades for single use are superior to sawblades that can be resharpened.

Sawblades that can be reground are instable in performance, especially after they have been reground a few times. Sawblades for single use provide the same cut quality cut after cut, blade after blade.

Sawblades for single use can be run until they suffer substantial damage. Sawblades that can be re-sharpened should be taken off the machine earlier to avoid such damage. For that reason, Novametal Pro DIA outlasts conventional PCD sawblades.

For various applications, sawblades with positive or negative hook angle are available

- The User Value is

-

-

Extensively longer life time than tungsten carbide tipped sawblades

-

Outperforms regular PCD sawblades

-

More machine uptime

-

High process reliability due to single use concept

-

Maintenance free

-